Win more bids with a Corrosion (MIC) Prevention Solution that lowers 15-year wet system cost and comes with a Third-Party Backed 15-Year Leak Warranty

Corrosion (MIC) Prevention Solution: Our Clean-Interior Steel Fire Sprinkler Pipe + Nitrogen Inerting (WPNI, O₂ ≤ 2%) with our Third-Party Backed 15-Year Limited Leak Warranty issued directly to building owners in Wet Sprinkler System by FireSprinklerPipe.com Steel for fire exposure—without the corrosion anxiety

For Fire Protection Contractors:

Grow your fire protection business.

Small changes, Big profits: Do you want to win more bids at lower prices and achieve higher profits — while securing maintenance and inspection work along the way? Our Corrosion (MIC) Prevention Solution: our clean-interior steel fire sprinkler pipes + Nitrogen inerting (WPNI, supplied by Tyco, ECS, Potter, or equivalent) with our Third-Party Backed 15-Year Leak Warranty in wet sprinkler system make it possible.

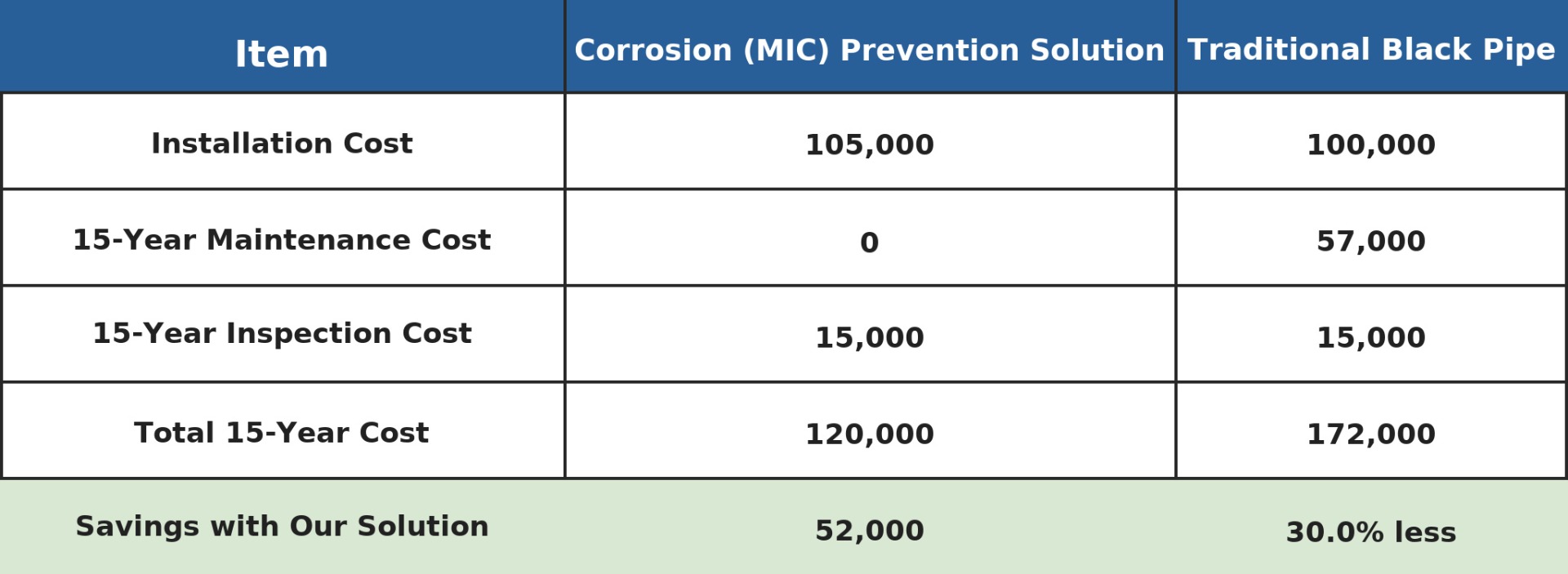

You can offer a compelling package: "New system installation + 15-year NFPA 25 inspections + 15-year oxygen control (nitrogen inerting) and re-inerting + a third-party backed 15-year manufacturer leak warranty issued to the owner" — all at a total cost that's at least 30% lower than traditional solution:

The following is a comparison table of the 15-year total costs of Corrosion Prevention Solution and Traditional Black Pipe in wet sprinkler system.

What this means for your business

- 15-Year Warranty → Predictable Costs → Smarter Bid:

With a third-party backed 15-year manufacturer leak warranty, your 15-year system costs become predictable, so you can set confident, competitive bid prices while protecting your margins. - Win More Bids with 30% Lower Total Cost over 15 Years

Our Corrosion (MIC) Prevention Solution is designed to deliver a 15-year total cost that is typically at least 30% lower than standard black steel pipe—making it easier for you to win more bids. - Pipe Is a Small Cost—The Savings Are Not

On any fire sprinkler project, pipe is only a small portion of the total installed cost. By reducing corrosion, leaks, and premature replacements, our solution turns that small material choice into major savings over the life of the system and a lower 15-year total cost. - Capture Leak-Repair Profits Up Front in the Original Bid:

As an Authorized Contractor, you can price new installations to reflect the 15-year leak-free value you're delivering to the owner. In practice, this lets you move profit that would normally come from unplanned leak repairs into the original project bid. - Secure Recurring Revenue with Warranty-Linked Services:

At the same time, you maintain steady recurring revenue from NFPA 25 inspections and the ongoing oxygen / nitrogen control and re-inerting work required under our program, since the owner's 15-year leak warranty depends on that service being performed and documented by you. - Reduce Emergencies and Focus on High-Margin Installations:

By greatly reducing internal-corrosion leaks, you spend less time on emergency callouts and can keep your fitters focused on scheduled, higher-margin installation work.

Want to see why steel is still the only material that never compromises on fire exposure?

Learn more in Why steel.

Our External Galvanized Internal Black Clean-Interior Steel Fire Sprinkler Pipe

How it works on your projects

Step 1 – Start with clean-interior pipe

Use our UL/cUL listed clean-interior steel fire sprinkler pipe in the wet system. It installs like standard steel but is manufactured to minimize interior residues that can accelerate internal corrosion.

Want the technical details? See "How to Prevent MIC"

Step 2 – Commission at low oxygen (O₂ ≤ 2%)

At handover, work with your nitrogen system vendor (Tyco, ECS, Potter, or equivalent) to perform Wet Pipe Nitrogen Inerting (WPNI) and NFPA 13 air venting. The goal is an oxygen level of ≤ 2% at representative high points, documented in your handover package.

The science behind low oxygen is explained in "How to Prevent MIC".

Step 3 – Document and maintain

You perform NFPA 25 inspections, testing, and maintenance, plus annual oxygen spot checks and re-inerting after major water additions or significant modifications. Keeping records (NFPA 25 reports, O₂ logs, re-inerting records) maintains the system within the design envelope.

Step 4 – Issue the owner's 15-year leak warranty

Once the system is installed, inerted, and documented according to the program, we issue a project-specific 15-year limited leak warranty certificate directly to the building owner for qualifying through-wall leaks in our pipe. You remain their NFPA 25 and nitrogen service provider.

Why nitrogen / WPNI vendors (like ECS, Tyco, Potter) like this solution

For AHJ-reviewed projects

We provide a complete acceptance package—including UL & cUL listing, O₂ ≤ 2% inerting logs (WPNI, supplied by Tyco, ECS, Potter, or equivalent), NFPA 13 air-venting and a Clean-Pipe Evidence Pack—so reviewers can make an informed approval based on documented outcomes.

If you have any questions regarding fire protection contractors, please see "FAQ–FPC".

If you need specifications and certificates, please see "SPECS, UL & cUL".

Why Do Your Customers Love Our Products?

Significantly Reduced Total Cost of Ownership (TCO):Our pipes are priced slightly higher than traditional fire sprinkler pipes, but our Corrosion Prevention Solution extends their lifespan, significantly reducing the Total Cost of Ownership (TCO) for your customers. In an era of soaring steel prices, it's more important than ever to spend wisely.

Dependable in Emergencies: Our solution maintains full functionality during fires, providing safety when it matters most. According to NFPA's national research, the leading cause of sprinklers failing to operate is that the system was shut off before the fire, often due to leaks, thereby making them ineffective when needed most. An NFPA analysis of U.S. fires from 2010–2014 found that three out of every five (59%) non-operations were due to shut valves often due to leaks.

Attractive for LEED Green Building Projects: Our solution supports sustainability by reducing replacement frequency, minimizing material waste, and meeting environmental standards.

For more details about Building Owners, see "For Building Owners".

The Advantage of Our Third-Party Backed 15-Year Limited Leak Warranty:

- Owner-facing, manufacturer-backed: For each qualified project, we issue a project-specific 15-year limited leak warranty certificate directly to the building owner, so the owner knows the pipe manufacturer stands behind the system.

- You keep the maintenance revenue: The warranty is conditional on NFPA 25 inspections, oxygen measurements and re-inerting after major water additions — work that must be performed and documented by you. The owner's warranty depends on your ongoing service.

- Easier to win bids: With virtually no unplanned leak repairs expected from internal corrosion in our pipe, you can offer predictable lifecycle costs and a stronger value story than traditional black pipe.

- Maximize customer lifetime value: An owner-facing warranty that depends on your NFPA 25 and WPNI service helps you secure long-term maintenance and inspection contracts instead of one-off repair work.

Want the Third-Party Backed 15-Year Limited Leak Warranty details? See "Leak Warranty"

The warranty is offered solely by us; WPNI or equivalent providers are not co-warrantors.

Corrosion caused by MIC leads to pipe leakage within 12 to 15 years. This means that if there is no pipe leakage within 15 years of use, leaks due to MIC will not occur. Therefore, if no leakage happens during our warranty period, it indicates that, with routine nitrogen inerting performed, the pipes will not leak in the future and the pipes can last for 50 to 70 years, similar to the lifespan of steel pipes several decades ago, before the impact of MIC.

Our company is a Clean-Interior Steel Fire Sprinkler Pipe manufacturer that sells directly to customers.

We also provide extra steel pipe to be stored by the contractor or owner so that repairs can start immediately without waiting for international shipments.

If the time from project acquisition to installation is short, it's not difficult, as long as you own or rent a warehouse to stock our steel pipes, you can start a business with unlimited potential for future development.

Debris-Free Easy Installation, Lower Costs:

- With a Fabrication Shop: With our "Debris-Free Easy Installation," which simplifies the processing procedure, you can significantly reduce the factory work required for each project. This allows your factory to greatly expand its capacity to take on more projects, thereby significantly increasing your revenue.

Without a Fabrication Shop: "Debris-Free Easy Installation" requires only minimal processing, such as cutting and grooving the steel pipes at the job site, and enhances installation efficiency.

What is Debris-Free Easy Installation: Our innovative pipes simplify the installation process. Simply cut the pipes to the lengths specified in the blueprint and connect them using Threaded Outlet Couplings with Gaskets to assemble the entire wet sprinkler system directly. Designing the blueprint with uniform pipe lengths (e.g., our standard lengths) can further streamline on-site installation, saving time and labor. Additionally, we offer grooving services for both ends of the pipes to meet your specific project requirements.

Our Corrosion (MIC) Prevention Solution —clean-interior UL & cUL steel fire sprinkler pipe + nitrogen inerting (WPNI, supplied by Tyco, ECS, Potter, or equivalent) + NFPA 13 air venting + documentation—delivers the following Competitive Advantages:

- Spec-ready acceptance: Submittals include a Clean-Pipe Evidence Pack, an O₂ ≤ 2% acceptance log at representative high points, and NFPA 13 air-venting confirmation—helping AHJs approve faster.

- Fewer callbacks: Clean interiors and a documented low-oxygen handover reduce early deposits/biofilm and the risk of under-deposit/MIC-related issues.

- Third-Party Backed 15-Year Limited Leak Warranty issued directly to owners: When installed and maintained per program, our pipe in the wet sprinkler system is covered for qualifying leaks caused by internal corrosion (including MIC). We issue a project-specific warranty certificate directly to the building owner, while the fire protection contractor keeps the NFPA 25 and WPNI service revenue.

- Lower lifecycle cost: An outcome-based approach (no chemicals left in service water) helps lower TCO by reducing leak repairs and unplanned shutdowns. A simple TCO worksheet is available upon request.

- Fire exposure ready: Noncombustible steel is suitable for fire exposure and looks clean in exposed installations thanks to its exterior galvanized finish.

- Simple upkeep: No ongoing chemical program—just annual O₂ spot checks and re-inert after major water additions to keep oxygen low.

- Sustainability minded. Steel is recyclable and durable; longer service intervals mean less replacement waste and may support owner sustainability goals.

- No internal zinc coatings: We do not rely on internal galvanizing or in-service chemical additives; control is achieved through cleanliness + oxygen management + documentation.

Josh is a clinical attending physician with a background in microbiology who entered the fire protection industry after seeing how severely Microbiologically Influenced Corrosion (MIC) can damage steel fire sprinkler pipes. By applying microbiology and field experience to pipe manufacturing and system design, he helped develop the Corrosion (MIC) Prevention Solution we use today – strong enough that we are prepared to back it with a third-party backed 15-Year Limited Internal Leak Warranty in wet systems.

Manufacturing Clean-Interior Steel Fire Sprinkler Pipes is a complex and meticulous process. If even one small step is incorrect, the pipes will lose their ability to prevent MIC. We have invested a great deal of time and money in continuous research and development, finally developed solution that truly prevent MIC, solving one of the most challenging problems in the global fire protection industry. Therefore, we have great confidence in our product and can guarantee its MIC prevention capabilities without any doubt, offering a 15-year Leak Warranty, which is unmatched in the industry.

If you have any questions about our product, please contact us.

or Contact Us

Here is a picture of Microbiologically Influenced Corrosion (MIC).